Finishing/Silkscreen

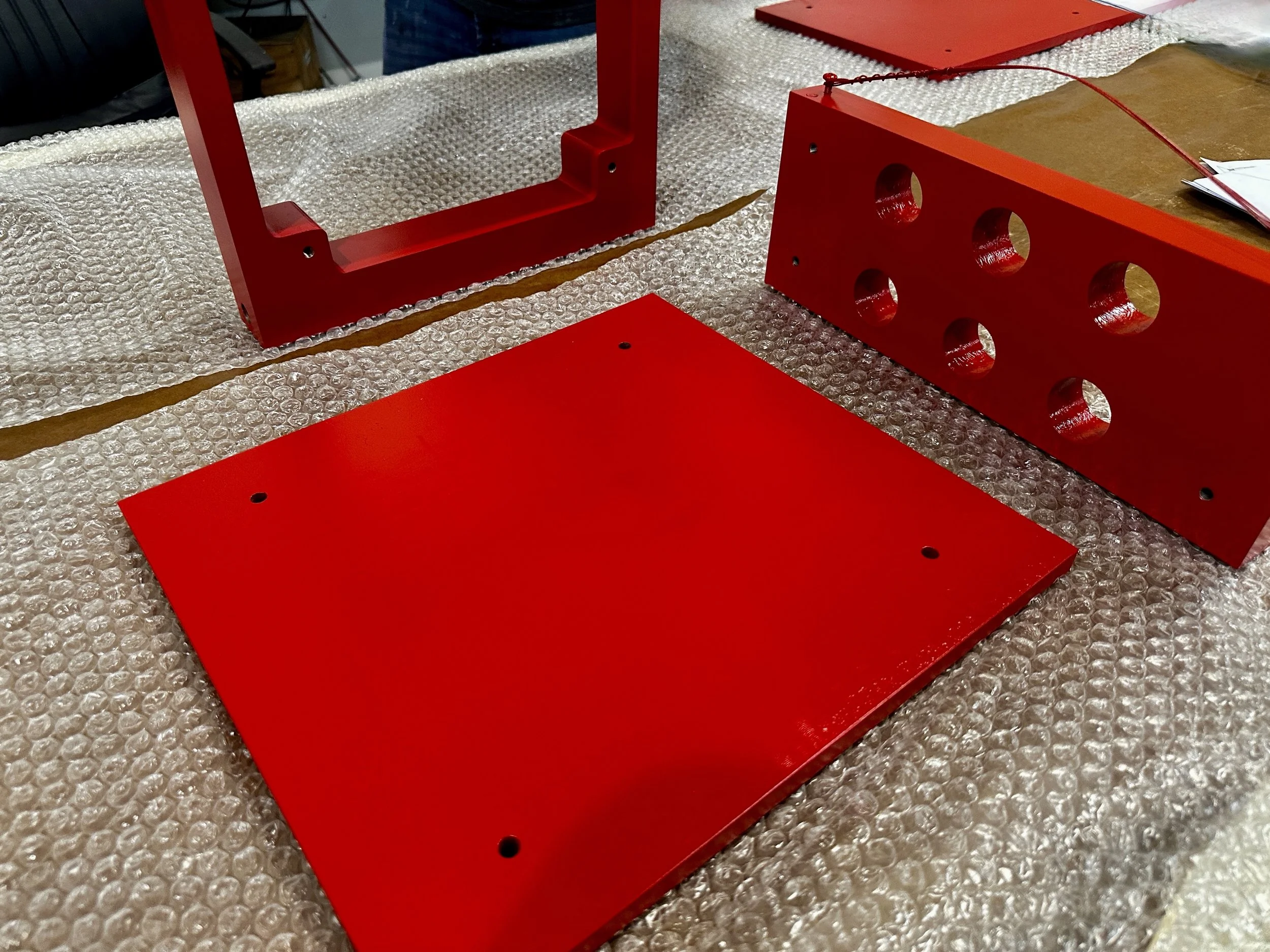

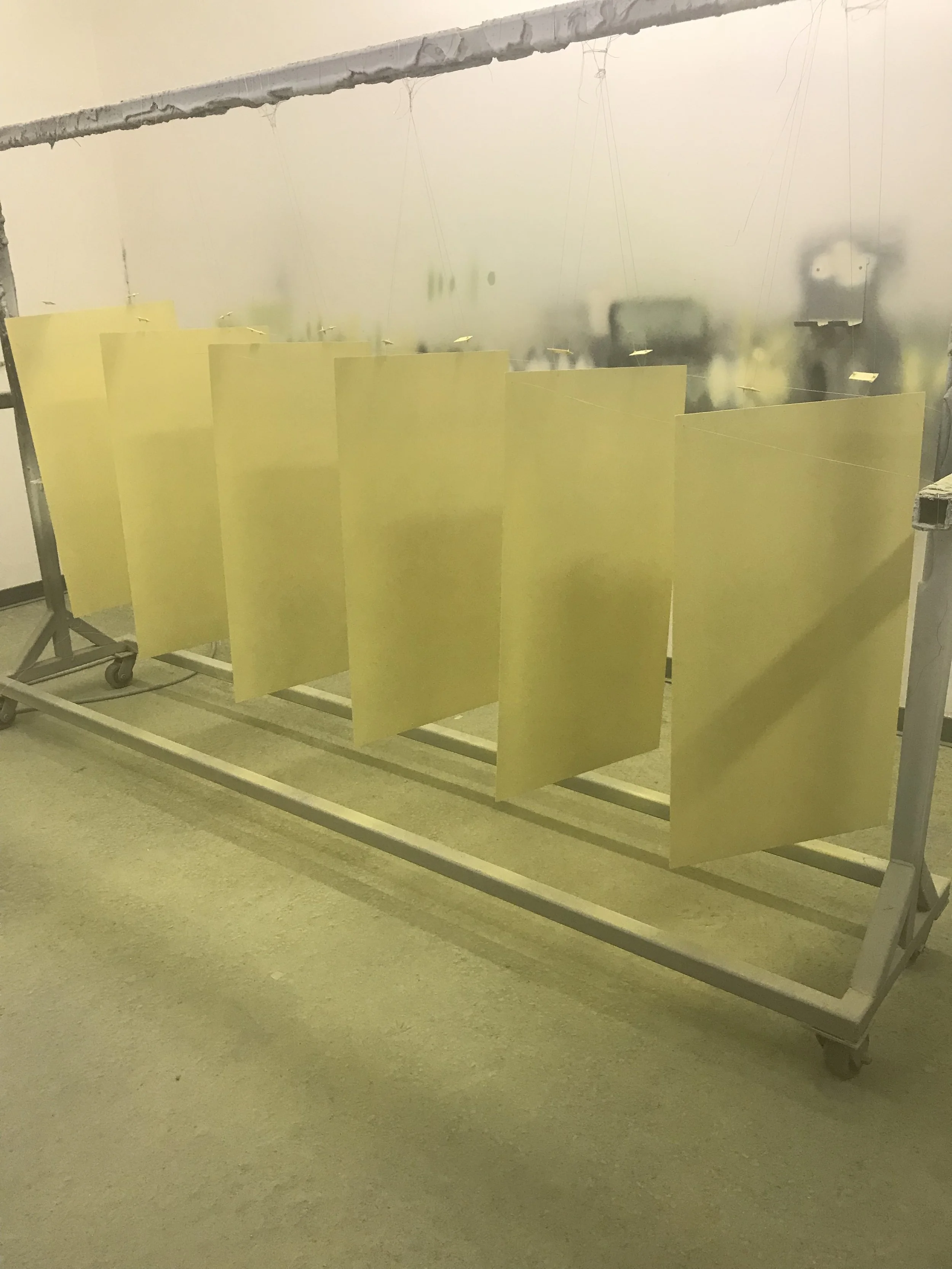

Following fabrication and assembly, parts head to the Finishing Department for alodine, prime, paint, heat treat, part marking and silkscreen as needed.

A steady flow of work at VISION MT has motivated growth and expansion in the scope and magnitude of our services and equipment. We are constantly driven to establish organic capability so that we retain as much control as possible over quality and lead time for all our awarded tasking. Silkscreen, heat-treat and CMM are some of the newer capabilities added in recent years. Bringing these functions in-house has allowed us to be even more responsive to evolving design requirements and artwork changes.

Technicians remove imperfections in the metal followed by chemical conversion and then dip in Alodine for a corrosive resistance coating as specified by drawings. Silkscreen, heat-treat, anodization, and passivation are some of the newer capabilities that allow us to be even more responsive to evolving design requirements and artwork changes.

Our in-house Heat Treat technology allows VISION MT to offer quicker turnaround times to our customers with parts requiring Heat-Treating, Annealing, and Aging. The chamber reaches temperatures up to 1200 degrees and has the capacity to work on parts up to 24”W x 16”H x 48L.

Our anodizing process enhances surface durability, corrosion resistance, and appearance for aluminum components, while passivation ensures stainless steel parts achieve optimal protection and longevity. By performing these finishing processes internally, we reduce lead times and deliver consistent, high-quality results.

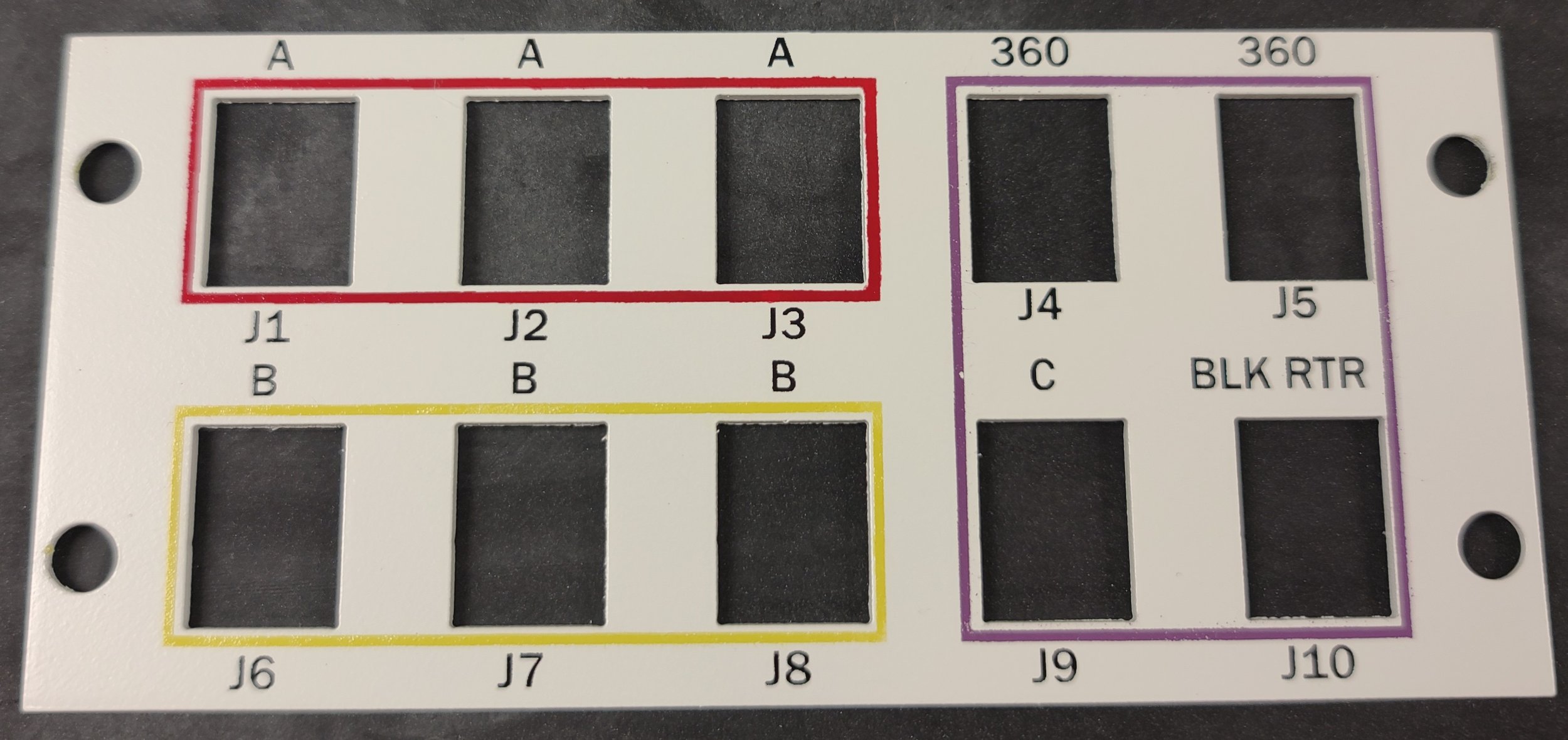

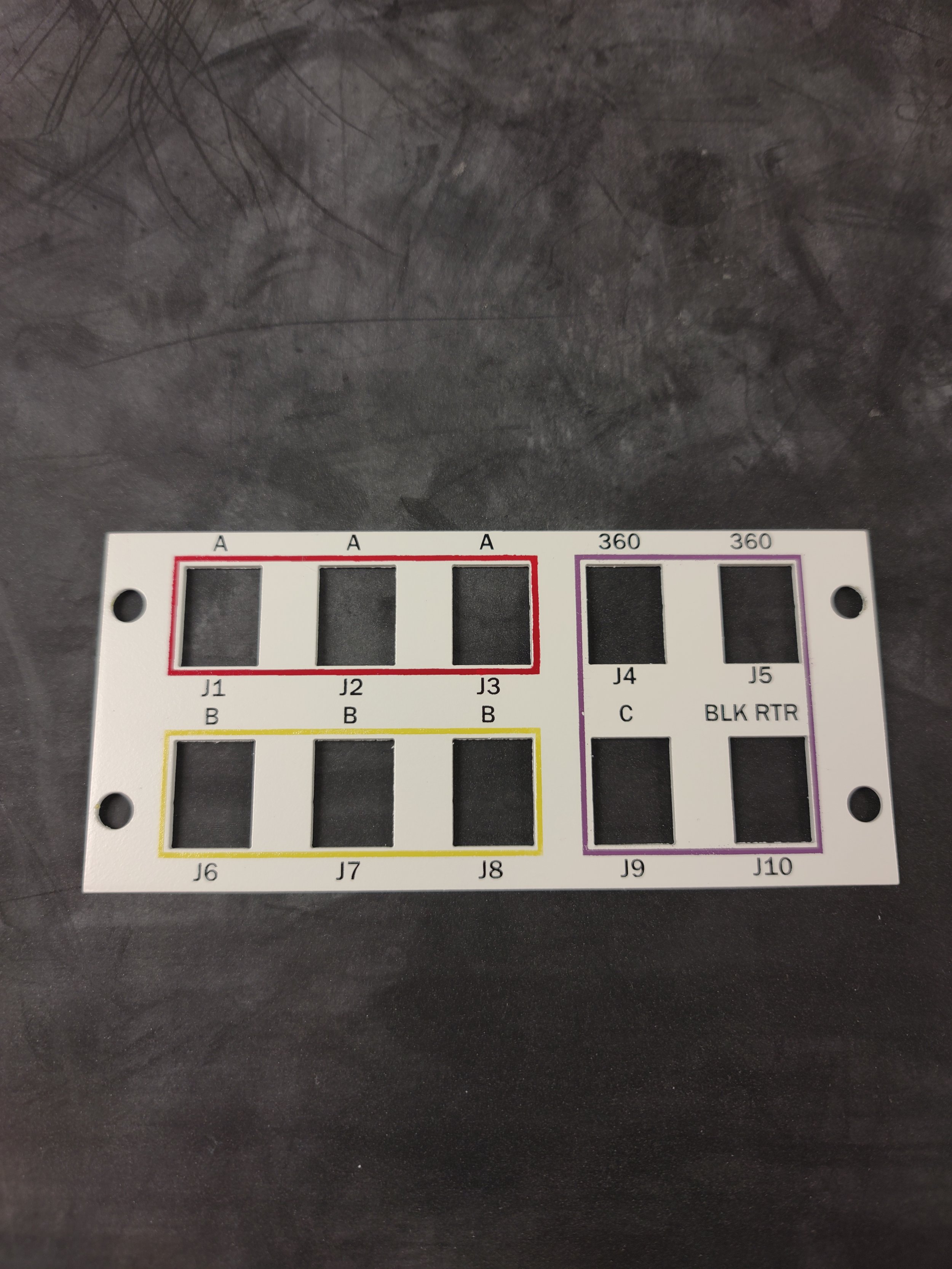

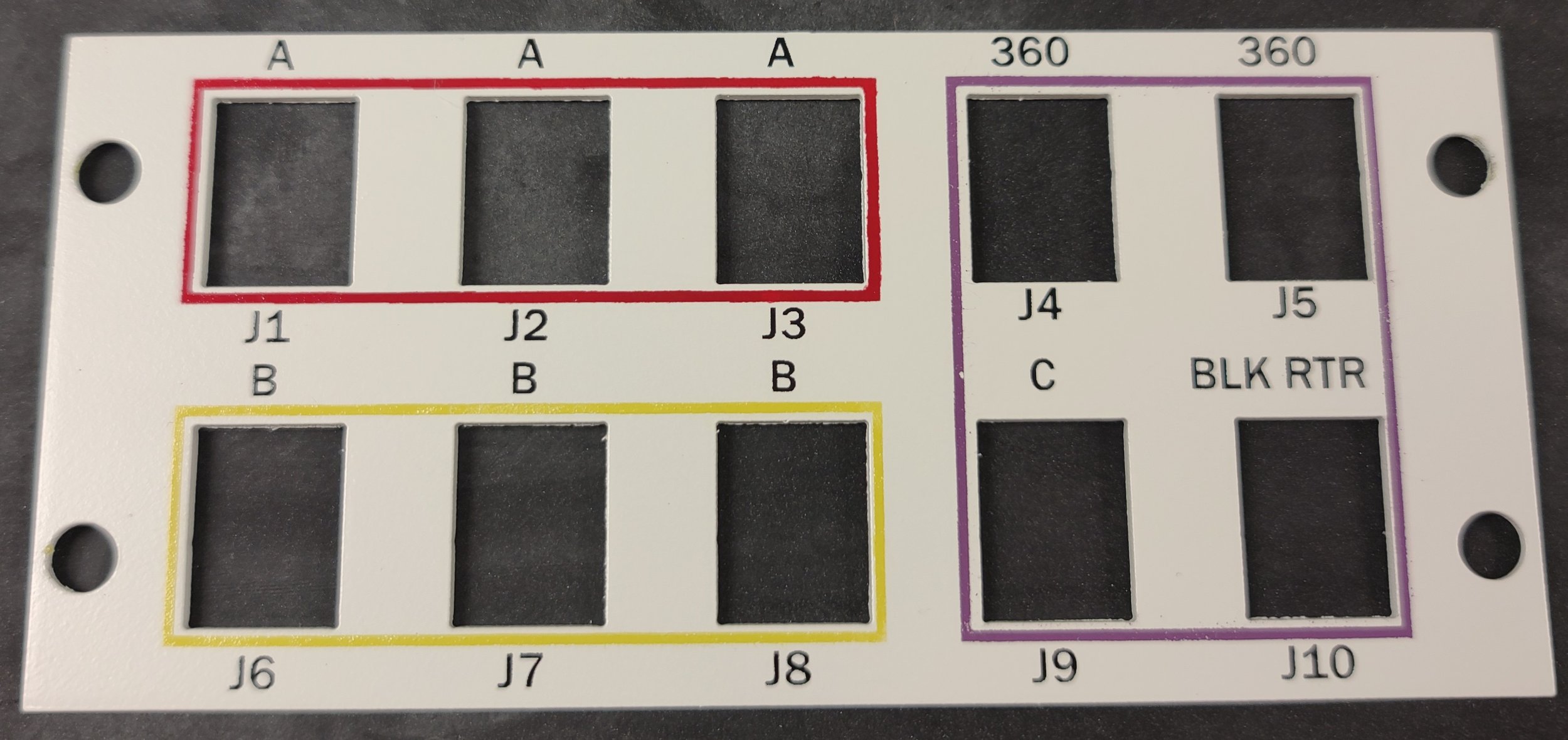

Silkscreen printing adds the final touch by transferring clean, precise graphics through a fine mesh stencil, ensuring sharp, durable markings. This controlled process allows us to apply each color with accuracy and consistency, completing a fully finished component ready for delivery.

Equipment Includes:

Brady Printer BBP12 – markers, sleeves, shrinks and wraps

TE Printer

Paint Booth – enclosed finishing booth with high efficiency filtered intake doors; Binks Trophy series HVLP sprayer.

Chem Coat, Prime, Anodization, and Passivation Stations

Part-marking machine - Videojet 1860

Silkscreen Press - TECHTONGDA 11TM SINGLE COLOR SCREEN PRINTING MACHINE - Holds burned screen onto piece to be silk screened while ink is applied

Power Washer - GREENWORKS 1500 PSI - To remove Emulsion and Ink from Screens

Exposure Unit - TECHTONGDA SPE-LEDSBJ6070 VACUUM UV EXPOSURE UNIT - Burns image from transparency onto the screen

SS Printer - EPSON WORKFORCE WF-7840 - Used to print transparencies that burn image onto the screen

Dip Tank/Wash Station – holds silkscreens for cleaning/cleans non-exposed emulsion before printing

Dark Room Lighting – used not to over expose image

OMTech Pronto 40 - CO₂ laser system designed for precision engraving and cutting on various materials with accurate, repeatable performance.

Dot-Peen Part Marking Machine – A mechanical marking method that uses a carbide pin to create precise, permanent dot impressions for part identification and traceability.