CMM & Non-Destructive Testing

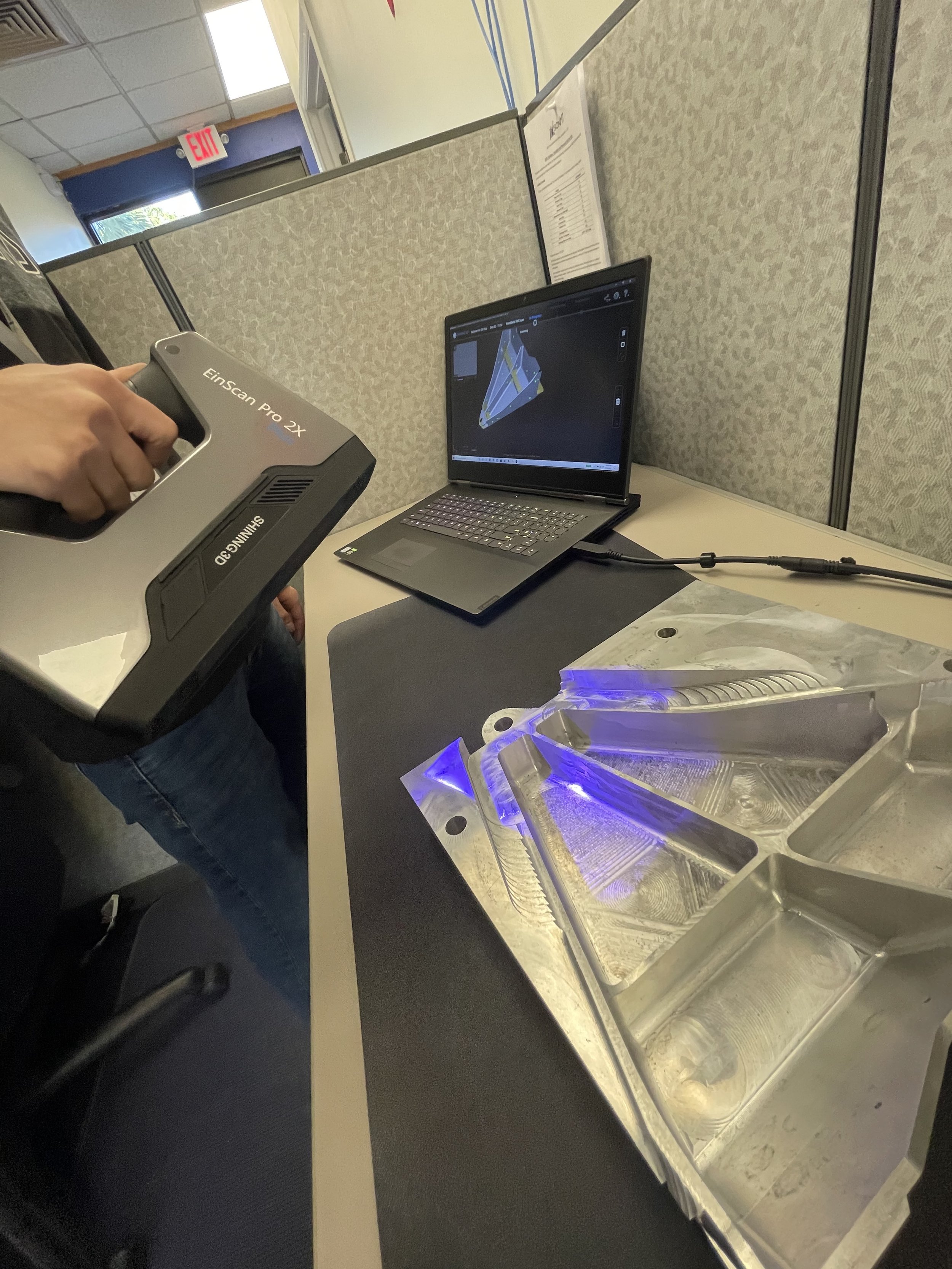

VISION MT utilizes advanced CMM technology for precise 3D measurement, inspection, and engineering for manufacturing. This process captures exact coordinate points with micro-precision, ensuring every build meets tolerance requirements and upholds the highest standards of Quality Assurance. With multi-axis visibility, we can quickly obtain a full range of precise measurements, strengthening our ability to validate components with the most complex geometry. Parts are delivered with documentation of inspection results.

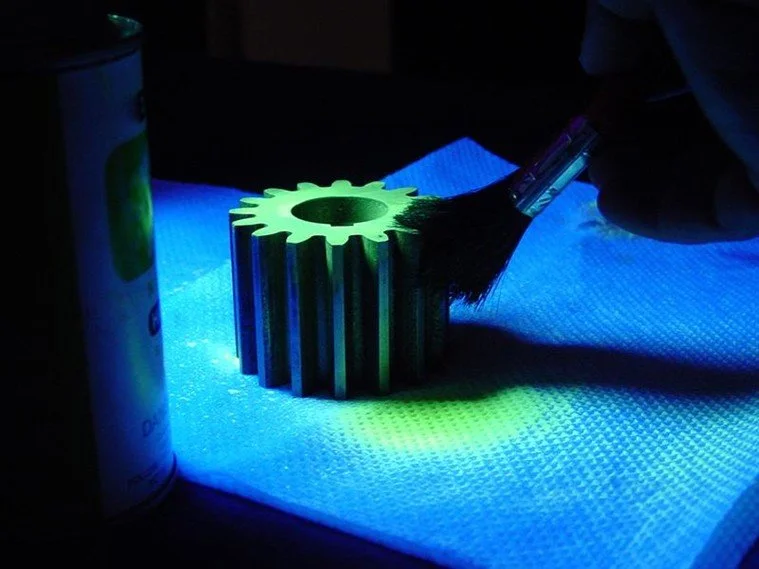

VISION MT performs in-house Non-Destructive Testing (NDT) to verify the integrity of components per customer requirements. Our certified team conducts dye penetrant (PT) and ultrasonic (UT) testing to ensure there are no surface or sub-surface flaws without damage to the part. Conducting these tests in-house meets our AS9100 certification, shortens lead times, and ensures consistent quality and reliability for our customers.